WHERE IT ALL STARTED

For more than 4 decades

Rotair’s performance in supplying quality helicopter replacement parts has made the company the industry leader. It is a reputation that has come about through continual striving for excellence in every area of our business.

The parts you purchase from Rotair meet all the design and performance requirements of the original component. Testing to and frequently beyond specification is standard procedure. This helps assure that only conforming parts are shipped to our customers. Rotair’s precision extends beyond product quality into such areas as technical support, research, inventory control, record keeping, and packaging and shipping. Around the world, Rotair is your number one source for most Sikorsky and selected Bell helicopter components. We are prepared to prove that we offer you levels of precision, availability, and service unsurpassed by any other source.

Rotair has the experience to manufacture parts that match the performance of the original components, and extensive experience in overhaul and repair, especially for UH-60 components.

Our people are the key. They have years of experience in the design, engineering and production of critical helicopter parts, much of it gained with Sikorsky and other leading aircraft manufacturers. Because of our backgrounds, we understand the importance of strict attention to detail in every phase of manufacturing, assembly and testing.

In short, we have the ability to recognize perfection, and we strive for it in every aspect of the service we provide.

The right tools

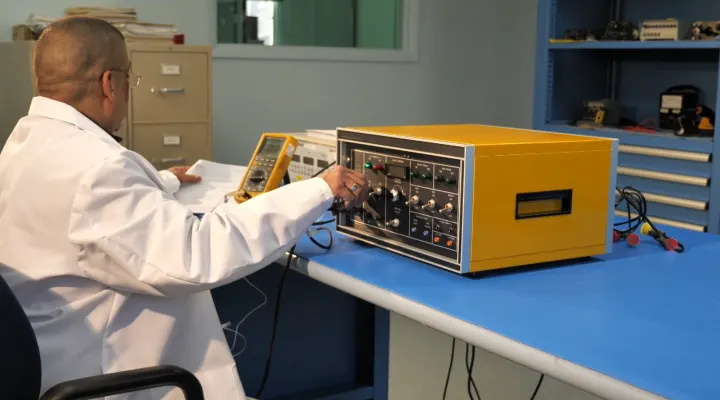

Rotair employs the latest in high technology inspection and testing equipment.. Typical of this advanced equipment is a coordinate measuring machine offering the fastest and most accurate checking of parts against specifications, and a Bendix 6040 Formax™, to measure and record the geometry of round parts with extreme precision. Rotair has invested millions of dollars in inspection and production testing equipment. The specialized equipment in our environmentally controlled inspection area includes a complete selection of hardness testers, optical comparators, an electronic surface finish instrument, film and plating thickness testers, as well as a complete array of gauges and measuring instruments. Our production department employs sophisticated testing equipment including a test vibration system, a computer controlled environmental chamber capable of cycling from -87° to +191° Celsius, electrical, hydraulic, and pneudraulic test stands, and sophisticated avionics test equipment. Complementing these capabilities is a Class 100,000 “Clean Room” capable of exceeding Class 10,000, if required.

Just for the record.

Quality is our foundation. Rotair’s commitment to quality is reflected in everything we do, from the purchase and inspection of the simplest standard hardware, through carefully documented processes, to the production of our most complex components. This commitment to quality extends to final inspection, packaging, and shipment to the customer. Our stringent quality procedures require that we maintain complete records on the manufacturing, testing, and inspection of all components and we employ digital bar-coding with computerized manufacturing and inventory control to help manage the process. Significantly, our Quality Assurance department reports directly to the President. The quality process includes on-site surveys of our subcontractors—reaching down to the lowest tier vendors— before orders are placed. We thoroughly check parts and components arriving at our plant against drawings and specifications before acceptance. Subcontractor product is subject to continuous inspection during the entire production cycle. Our Technical Data Department maintains up-to-date drawings and specifications to ensure that all information is current, complete, and legible.

WE STRIVE FOR EXCELLENCE

The pursuit of perfection.

We strive for excellence in every aspect of the services, parts, and products we provide. The result of this attention to quality in our organization and our procedures is a proven record of excellence. Our parts are as reliable as those of the original manufacturer and often preferred by our customers. Rotair maintains a vast inventory of parts, many not available from any other supplier. Allow us to show you how our team of perfectionists can provide you with the safest and most reliable parts and services available anywhere.

Rotair is the most comprehensive source anywhere for FAA-PMA approved parts with over 3000 PMAs currently held.

QUALITY AND PROFESSIONAL

Parts Specialists for Rotary Wing Aircraft

For more than four decades, the performance of Rotair Aerospace Corporation in the supply and manufacture of quality helicopter parts has made it an industry leader. It is a reputation earned through the achievement of excellence in every facet of the business.

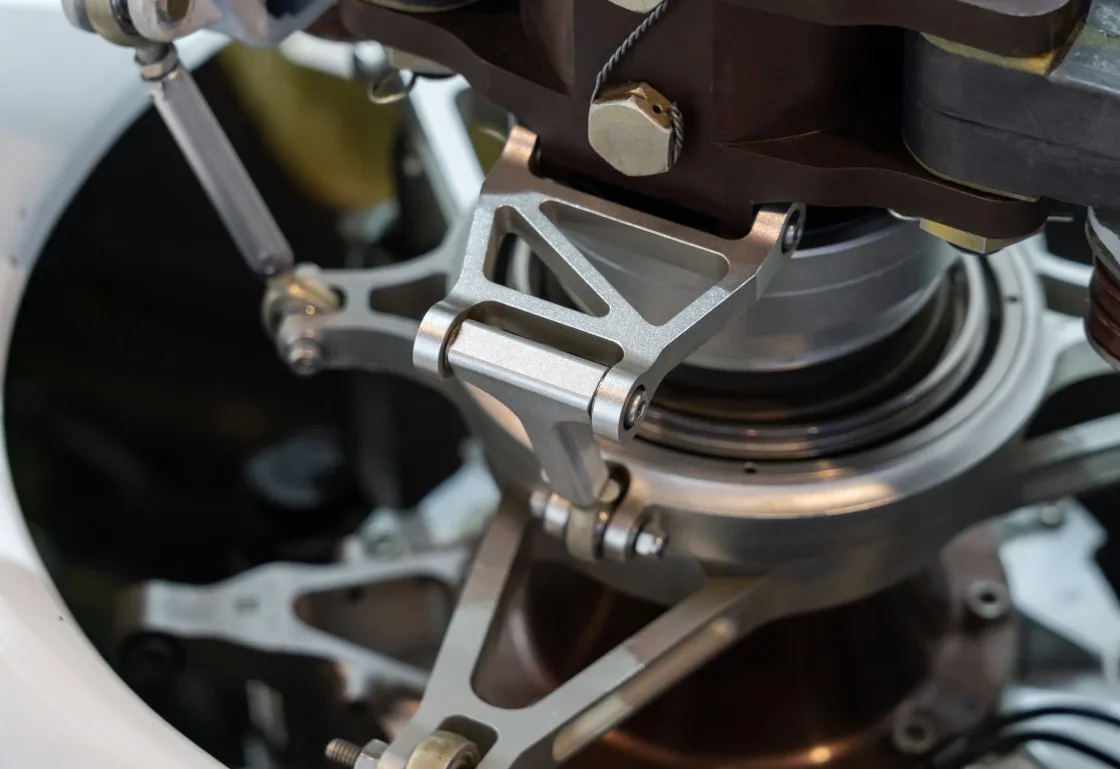

Rotair is expert in the manufacture of complex replacement helicopter avionics, hydraulic and mechanical parts and systems such as flight controls, bifilar assemblies, and rotor components.

PRESICION IS KEY

Our success is the sum of all parts

Parts provided by Rotair—at a minimum—meet the design and performance requirements of the original component. Testing to specification and inspecting all critical characteristics of a component is standard procedure. It helps guarantee that only conforming, reliable parts are shipped to our customers—contributing to safer operations. The same standard of excellence extends into all departments including production planning, assembly, inventory control, record keeping, packaging, shipping, and technical support.

EXPERIENCED AND QUALIFIED PERSONNEL

The right stuff

Our people are the key to Rotair products and services. We proudly attract and retain top personnel. They have years of experience in the design, engineering, and production of complex helicopter parts. Because of our specialization in rotary-wing components, we understand the importance of strict attention to detail in every phase of manufacturing, assembly, and testing. Our creative engineers have innovated proprietary systems, tools, and fixtures which ensure that the fabrication of components results in the highest quality items. Symbolic of our regional heritage and spirit, our Bridgeport facility is located in a historic, refurbished nineteenth-century factory housing two of Connecticut’s oldest elevators. Rooted in the tradition of Yankee ingenuity and coupled with the Information Age vision, the innovators of Rotair possess an unparalleled pride in their craft.

REGULATED AND COMPLIANT

Held to the highest standards

The Rotair Aerospace Quality Management System (AQMS) meets the highest standards of compliance in the aerospace industry. Our AQMS is registered with the International Organization for Standards under current ISO 9001 and AS9100 certifications. The system also conforms to U.S. Federal Aviation Administration (FAA) Part 21 requirements for Parts Manufacturer Approval (PMA). As an FAA Repair Station, Rotair has the capability to overhaul and repair all makes and models of Sikorsky and Bell commercial helicopter components under FAA Certificate # OHBR591K.

PEACE OF MIND

Compliance and Conformance

Committed to the highest business and personal ethics — legal, moral, ethical

Dedicated to our customers, our employees, and their families.

In full compliance with Departments of State, Commerce, and Defense

We make quality helicopter parts, meeting or exceeding all design and performance requirements.

Rotair is an authorized FAA Repair Station, Certificate # OHBR591K.

Commitment reinforced with frequent, tailored training.

OUR OUTREACH

Community Support

United Way

Boy Scouts

Other charitable organizations